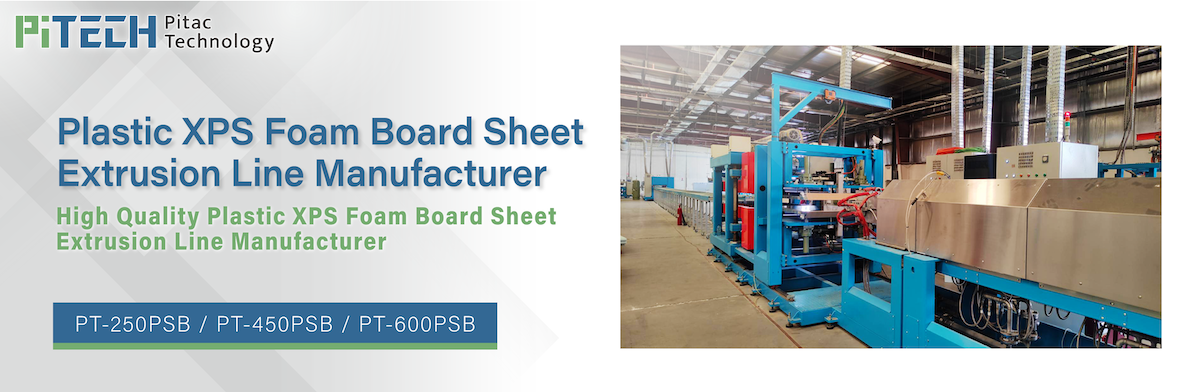

PiTECH is the world's leading manufacturer of plastic foam extrusion systems. According to customer needs, we not only provide manufacturing expertise for polystyrene foam sheets but also provide complete integrated technical services. Plastic XPS Foam Board Sheet Extrusion Line Manufacturer is one of the products we specialized in. Can't wait to hear from you. Contact us now!

- Material: GPPS

- Material Thickness: 25-100 mm (details see specification)

- Output: 250-600 kg/hr (details see specification)